The project is 95% complete. The GC sends an email: "O&M manuals due in 10 days."

Now you're scrambling. Chasing manufacturer literature. Tracking down warranty certificates. Trying to remember what equipment got installed where.

This scramble is preventable.

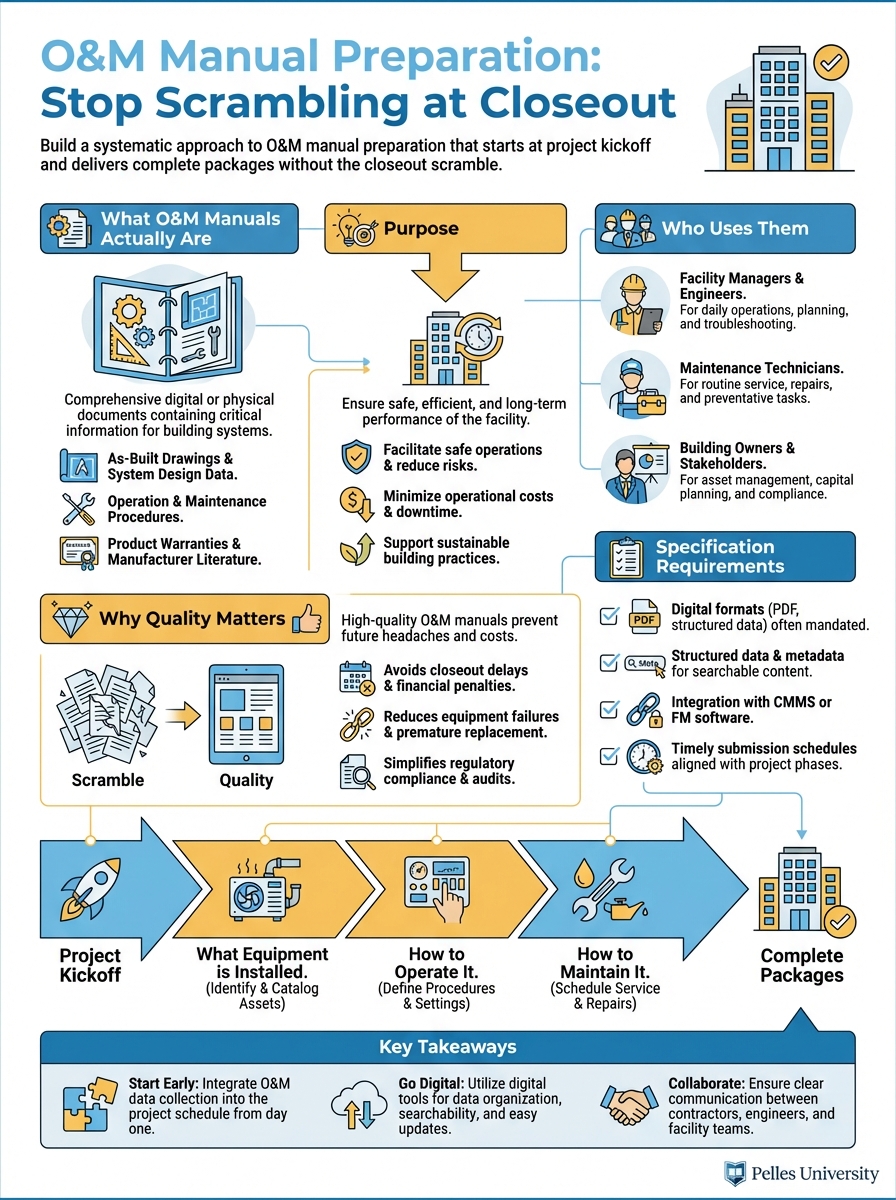

What O&M Manuals Actually Are

Purpose

Operations and Maintenance (O&M) manuals tell the building owner:

- What equipment is installed

- How to operate it

- How to maintain it

- How to troubleshoot problems

- Who to call for service

They're the instruction manual for the building systems you installed.

Who Uses Them

Facility managers: Daily operations and maintenance scheduling

Maintenance technicians: Troubleshooting and repairs

Building engineers: System optimization

Future contractors: Understanding existing systems

Your O&M manual may be referenced for the next 30 years.

Why Quality Matters

Poor O&M manuals:

- Generate calls to you for information

- Cause maintenance mistakes

- Create liability exposure

- Damage your reputation

Quality O&M manuals:

- Enable proper maintenance

- Reduce post-completion support burden

- Demonstrate professionalism

- Build owner confidence

Specification Requirements

Finding the Requirements

O&M requirements typically appear in:

Division 01 (General Requirements):

- Section 01 78 23: Operation and Maintenance Data

- Section 01 78 36: Warranties

- Section 01 79 00: Demonstration and Training

Technical sections:

- Each equipment specification section may have additional requirements

Read both Division 01 and your technical sections carefully.

Common Requirements

Format:

- Binder type and size

- Tab organization

- Digital format requirements

- Number of copies

Content:

- Product data for all equipment

- Maintenance procedures

- Parts lists and sources

- Wiring and control diagrams

- Warranty information

Timing:

- Draft submission for review

- Final submission deadline

- Training completion

Sample Requirement Language

From a typical specification:

"Assemble O&M data into durable binders with identification on front cover and spine. Organize by specification section. Include equipment-specific information including nameplate data, installed location, and as-built settings."

The phrase "equipment-specific" is key—generic literature isn't enough.

Building the System

Start at Kickoff

During submittal processing:

- Create O&M folder structure matching spec sections

- As submittals are approved, file O&M-relevant content

- Note what's missing from each submittal

- Request missing information from vendors

Don't wait for closeout to start collecting.

Track Progress

Create an O&M tracking log:

| Spec Section | Equipment | Submittal | O&M Status | Missing Items |

|---|---|---|---|---|

| 23 05 00 | Hangers/Supports | Approved | Partial | Seismic certification |

| 23 31 13 | Ductwork | Approved | Complete | - |

| 23 34 00 | HVAC Fans | Approved | Partial | Wiring diagrams |

| 23 73 00 | Air Handling Units | Approved | Partial | Control sequences |

Review monthly. Chase missing items early.

File Organization

Physical binders:

Volume 1 - Mechanical

Tab 1: Section 23 05 00 - Common Work

Tab 2: Section 23 21 00 - Hydronic Piping

Tab 3: Section 23 31 00 - HVAC Ducts

Tab 4: Section 23 34 00 - HVAC Fans

Tab 5: Section 23 73 00 - Air Handling Units

...

Digital folders:

O&M Manuals/

01-Mechanical/

23-05-00_Common-Work/

23-21-00_Hydronic-Piping/

23-31-00_HVAC-Ducts/

...

02-Electrical/

26-05-00_Common-Work/

26-24-00_Switchboards/

...

Mirror the spec organization exactly.

Content Requirements

For Each Piece of Equipment

Basic information:

- Equipment tag/designation

- Manufacturer and model

- Serial number

- Location in building

- Specification section reference

Technical documentation:

- Product data sheet

- Installation instructions

- Operation instructions

- Maintenance requirements

- Troubleshooting guide

- Parts list

Project-specific:

- Nameplate data (actual ratings)

- As-built settings and setpoints

- Control sequences

- Wiring diagrams (as-installed)

Equipment-Specific Sheets

Create a cover sheet for each major piece of equipment:

EQUIPMENT DATA SHEET

Equipment Tag: AHU-1

Description: Air Handling Unit

Manufacturer: Carrier

Model: 39M10

Serial Number: 1234567890

Location: Mechanical Room 101

Specification Section: 23 73 00

Design Conditions:

Airflow: 5,000 CFM

Cooling Capacity: 15 tons

Motor HP: 7.5

As-Built Settings:

Supply Air Temp Setpoint: 55°F

Static Pressure Setpoint: 1.5" WC

Economizer Changeover: 55°F OAT

Local Representative:

Company: ABC Mechanical Supply

Contact: John Smith

Phone: (555) 123-4567

This makes the generic manufacturer literature specific to your installation.

Maintenance Schedules

Compile maintenance requirements into a usable format:

| Equipment | Daily | Weekly | Monthly | Quarterly | Annual |

|---|---|---|---|---|---|

| AHU-1 | Check filters | Check belts | Lube bearings | Inspect coils | Full PM |

| Pumps | Check operation | Check seals | Check alignment | Rebuild | |

| VAV Boxes | Check operation | Calibrate |

Owners appreciate consolidated maintenance information.

Warranty Summary

Create a warranty summary page:

| Equipment | Warranty Period | Start Date | Expiration | Contact |

|---|---|---|---|---|

| AHU-1 | 1 year parts | 03/15/25 | 03/15/26 | Carrier (800) 555-1234 |

| AHU-1 Compressor | 5 year | 03/15/25 | 03/15/30 | Carrier (800) 555-1234 |

| Controls | 2 year | 03/15/25 | 03/15/27 | Trane (800) 555-5678 |

Include warranty certificates behind the summary.

Common Problems

Problem: Generic Literature Only

Symptom: O&M consists of manufacturer brochures with no project-specific information

Solution: Create equipment data sheets with installed information. Add nameplate data, settings, and locations to generic documentation.

Problem: Missing Documentation

Symptom: Submittals were approved but O&M content wasn't included

Solution: Start tracking at submittal approval. Request missing content immediately, not at closeout.

Problem: Disorganized Content

Symptom: Information exists but can't be found

Solution: Use consistent organization matching spec sections. Create tables of contents. Use clear labeling.

Problem: Outdated Information

Symptom: O&M doesn't reflect as-built conditions

Solution: Update O&M content when changes occur. Incorporate as-built information from field.

Problem: Last-Minute Scramble

Symptom: Two weeks before closeout, nothing is assembled

Solution: Monthly O&M status reviews. Progressive assembly throughout project.

Working with Vendors

Setting Expectations

At purchase order:

- Specify O&M requirements

- Reference specification sections

- Include format requirements

- Set delivery timeline

Example PO language:

"Provide O&M documentation per specification Section 01 78 23 including product data, maintenance procedures, parts lists, and wiring diagrams. Submit with equipment delivery."

Following Up

If vendor O&M is incomplete:

- Document what's missing specifically

- Reference PO and spec requirements

- Set deadline for completion

- Escalate to manufacturer if needed

Make this a procurement issue, not a closeout issue.

Control Contractors

Controls documentation requires special attention:

- Points lists with descriptions

- Sequence of operations

- Graphic screenshots

- Trending setup

- Alarm configurations

- Network architecture

Get commitments for this documentation in the controls contract.

Digital Delivery

PDF Requirements

Most projects now require digital O&M:

Organization:

- Bookmarked PDF files

- Consistent file naming

- Hyperlinked table of contents

- Searchable text (OCR if needed)

File naming convention:

[Section#]_[Description]_[Equipment].pdf

Example: 23-73-00_AHU_ProductData.pdf

Building Management System Integration

Some owners want O&M linked to their BMS or CMMS:

- Equipment asset numbers

- Standardized naming

- Maintenance procedure codes

- Spare parts integration

Ask about these requirements early.

Cloud Delivery

Requirements may include:

- Specific platform (Procore, Box, etc.)

- Folder structure

- Access permissions

- Retention requirements

Understand the delivery method before assembly.

Quality Review

Self-Check Before Submission

Review each section for:

Completeness:

- All specified equipment covered

- All required documents included

- Equipment-specific data added

- Warranties included

Accuracy:

- Model numbers match installed

- Settings match as-built

- Locations are correct

- Contacts are current

Format:

- Organization matches requirements

- Tabs and dividers correct

- Cover and spine identified

- Page numbers if required

Draft Submission

Submit draft O&M for review before final:

Benefits:

- Identify missing content

- Clarify format expectations

- Avoid rejection at closeout

- Time to obtain missing items

Request draft review 60-90 days before closeout.

Using AI for O&M Preparation

Creating Equipment Sheets

Create an equipment data sheet template for an air handling unit

that includes:

- Basic identification (tag, manufacturer, model, serial, location)

- Design conditions (CFM, capacity, motor HP)

- As-built settings section

- Local representative contact section

- Reference to O&M binder location

Format for printing on one page.

Compiling Maintenance Schedules

Based on this manufacturer maintenance literature, create a

consolidated maintenance schedule table:

[Paste manufacturer maintenance requirements]

Format as:

- Equipment type

- Daily tasks

- Weekly tasks

- Monthly tasks

- Quarterly tasks

- Annual tasks

Checking Completeness

Review this O&M table of contents against the specification

sections listed below. Identify any missing items:

Table of Contents:

[Paste your TOC]

Required Specification Sections:

[Paste spec section list]

Note any gaps or potential missing content.

Timeline

Project Start (Month 1)

- Review spec requirements for O&M

- Create folder structure

- Set up tracking log

- Communicate requirements to vendors

During Construction

- File O&M content as submittals are approved

- Track missing items

- Follow up with vendors

- Collect as-built information

90 Days Before Closeout

- Complete review of tracking log

- Submit draft for review

- Chase all missing items

- Begin assembly

30 Days Before Closeout

- Incorporate review comments

- Complete equipment data sheets

- Compile warranties

- Final assembly and QC

At Closeout

- Submit final O&M

- Deliver training materials

- Obtain acceptance

What's Next

Complete O&M manuals are one part of closeout. They work alongside as-built drawings, warranty documentation, and training to give the owner everything they need to operate and maintain your installed systems.

TL;DR

- Start O&M collection at project kickoff, not at closeout

- Create equipment-specific cover sheets—generic literature isn't enough

- Organize by specification section to match project manual structure

- Track progress monthly and chase missing items early

- Submit draft for review 60-90 days before closeout

- Include warranties, maintenance schedules, and contact information